Except systems are particularly made for this, temperatures hotter than eighty˚C can effect the longevity of system components (e.g. gaskets and diaphragms). A temperature of eighty˚C is effectively scorching more than enough to get rid of quite possibly the most heat resistant biofilm organisms that should colonize a water system (D worth of about 5 milliseconds).

USP supplies answers to Regularly Requested Questions (FAQs) as a service to stakeholders and Other folks who are seeking information and facts relating to USP’s Corporation, benchmarks, requirements-location process, and various routines. These are definitely supplied for informational uses only and should not be construed being an Formal interpretation of USP textual content or be relied on to reveal compliance with USP specifications or necessities.

Distillation is effective in developing WFI that satisfies the demanding microbial and endotoxin specifications established by pharmacopeias.

Consequently, water necessitates chemical and microbiological control commensurate with its supposed application.

Before beginning phase-I, you need to conduct Demanding take a look at for Car dump valves and maintain time analyze. In the course of the period-I validation drain time study also to be done. ReplyDelete

For lab analyses, samples really should be saved in containers that don't adversely impression the examination benefits. This is certainly to forestall Wrong positives and unneeded investigations. For example, storage of water inside a glass container for a few hrs is normally excellent, but storage for a longer time will lead to a modest increase in the sample conductivity.

Water and steam may very well be Employed in the manufacture of products and solutions, cleansing operations, and laboratory functions inside of pharmaceutical or biopharmaceutical operations.

Sure. Both of these chapters exclusively condition that these tests is often done off-line or on-line. You can find benefits and challenges for each strategy, and they are more info described in additional detail in these chapters and in Water for Pharmaceutical Applications

At EMMA International, we realize the complexities of creating and preserving WFI systems that satisfy regulatory demands. Our staff of experts can support with all the things from designing WFI systems to making sure ongoing compliance with world wide pharmacopeia criteria.

SWFI system validation encompasses the validation routines of equally PW and WFI systems, with a further emphasis on demonstrating and sustaining sterility all through the distribution approach. The validation technique must incorporate validation of sterilization approaches, like steam sterilization or other validated techniques used for attaining sterility.

Water sampling and testing ought to be carried out for 2 to four weeks to monitor the water system. Through this stage, water system need to function repeatedly without having failure. Adhering to factors must be deemed through this section.

twenty mg/L of carbon or increased have to be identified, quantified, and have their basic safety profiles evaluated. How can this be completed?

Typically, water launch to be used must be determined by a POU sample reflecting production’s water use practices instead of on sample port facts.

Along with these primary methods, other purification methods read more like deionization, carbon filtration, and UV disinfection in many cases are A part of WFI systems to be sure the highest high-quality of water.

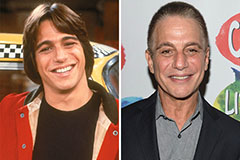

Tony Danza Then & Now!

Tony Danza Then & Now! Angus T. Jones Then & Now!

Angus T. Jones Then & Now! Michael Bower Then & Now!

Michael Bower Then & Now! Seth Green Then & Now!

Seth Green Then & Now! Barbi Benton Then & Now!

Barbi Benton Then & Now!